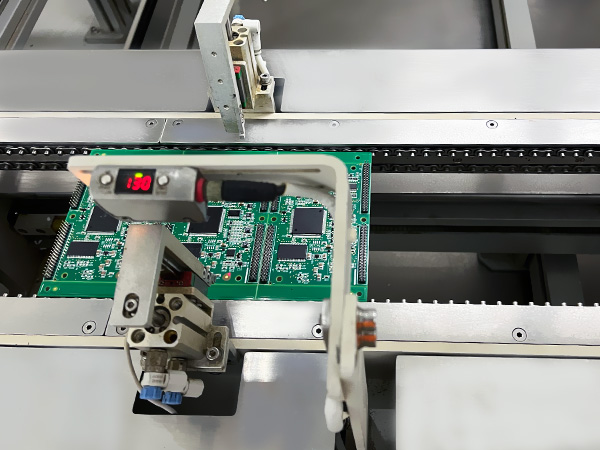

Selective Soldering of TH Components

The identification of new solutions, using the latest technology, indisputably leads to an increase in the efficiency and performance of the equipment used in various industries and fields of activity.

That is why our company is always concerned with the adoption, development, production and distribution of technologies for electronic components, which can bring real benefits in terms of the quality of the finished products obtained. Our concept always has in mind the improvement of the product, the shortening of the period necessary for the production of a part, a cheaper maintenance of the equipment that uses the obtained components.

In our EMS service area, since 2022, we have been providing all customers with the latest electronic circuit assembly and finishing technology, offered by the latest version of selective soldering equipment developed by Nordson (Integra series). It comes with many advantages over wave or manual soldering.

What is selective soldering?

The construction of a PCB (Printed Circuit Board) involves two production processes, namely manufacturing and assembly. Manufacturing involves building the physical structure of the board. The assembly is done when all the necessary electronic components are arranged and fixed on the board and what is called PCBA or Printed Circuit Board Assembly is obtained.

In order to give certain properties and help to increase the quality, functionality and strength of the board, it is very important how to assemble the components by soldering. The technological process is performed with a machine that solders the circuits and electronic components on the circuit board (printed). For this purpose, it is equipped with a program, sensors, a pumping system and a tank with soldering solution that will pass through several types of nozzles, accurately gluing the components through the bottom of the plates. The soldering solution is thus applied only in the contact areas which involve electrical contact between the components and the circuit board.

The mechanism used by this soldering method is designed for an assembly that moves in several directions and on several levels. These directions are coordinated by the use of software.

It is controlled by a specialized operator; customized programs can be developed for each circuit or panel on which the assembly will be done.

In addition to the special movement, the programming also allows the operating engineer to have control over the application time of the soldering and the temperature used during application. These details lead to more accurate fixing results and avoid overheating of areas or components, which can affect the conformity of the final product.

What are the benefits of selective soldering technology?

Computerized control of the processes of assembly and selective soldering comes with many advantages in the execution and the results obtained in the production of electronic panels and boards. The products made have much improved characteristics compared to those made by manual soldering or wave soldering.

In many industries, the trend is to eliminate the process of repairing soldering defects, to reduce waste of materials, costs and possible new problems. That is why a new technology, which minimizes all existing problems and risks and increases the efficiency of the processes involved, comes with many opportunities.

The most important advantages of selective soldering technology are:

- Significantly reduces the number of production defects;

- Provides an improved design for circuit boards;

- Provides greater accuracy in soldering all elements and components;

- Allows soldering, fixing and joining of different parts, made of different materials, on several levels;

- Allows soldering both horizontally and at various angles of inclination;

- Allows the achievement of very meticulous assembly tasks, of high complexity;

- The combination of several nozzles with soldering material and temperature control offers more security in performing the most complicated soldering processes, without affecting the plates or components;

- Uses less soldering solution;

- The temperature is controlled so as not to affect the quality of the board, circuits or other elements;

- More precision in the whole process and high compliance;

- Assembly is much faster;

- Processes can be customized on each project and also according to particular requirements;

- • It can also be used for products that involve soldering on two or more sides;

- The number of production errors is decreased.

In order to obtain the performances offered by the technology, we have trained the personnel who operate the soldering line (operators and engineers).

This new technology comes with many benefits for all those interested in increasing production capacity, increasing the quality of assembly services; flexibility in production, improved production terms and delivery conditions. It can be used successfully for custom, complex, small or large, high density component projects.